Improved economic, technological and sensory properties of prepared meat products.

Thanks to our 35 years of practical experience, we are able to offer you, through the PH Liquid buffer system, the world’s safest and best meat preparations for the following line productions :

Ham preparation

heating up to 72°C

All liver preparations

heating up to 72°C

Baked liver preparations

heating up to 85°C

All meat sausage preparations

heating up to 70°C

All salami preparations

buffer pH value 4.8 max. 5.2

All preparations have been improved as to their economic, technological and sensory characteristics, as explained below :

Economic improvement :

The correct choice of raw materials and composition of the product improves the yield, as does a more advantageous purchase system of raw materials, such as PH Liquid Extract, Buffer phosphates, Red Star Pickle and Dry Binder, Gela Gelatin.

The total purchased quantity is estimated on a yearly basis and the best prices are offered. Delivery is made monthly and on demand, with the guarantee that products of a constant quality are delivered.

Technological improvement :

By applying the appropriate buffer and Aw values for all product preparations, the following advantages are obtained :

- a shelf life of heated products that is twice as long

- improved taste and colour

- natural colour of the cutting surface maintained during a longer period of time

- stable PH value adapted to each individual product preparation

Sensory improvement :

- improved cutting or spreading properties, depending on the product

- more solid structure of each line product

- no discoloration of the cutting surface

- longer storage period in an ordinary refrigerator, thanks to the stable pH buffer value

You can also benefit from these advantages, without any major adjustments or capital investments. Just by choosing the appropriate formula and by adding the appropriate additives to your preparations, you will obtain a stable buffer system thanks to PH Liquid Extract and buffer phosphates.

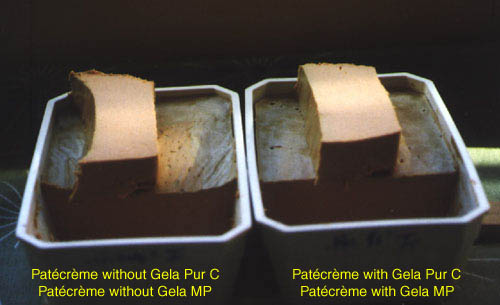

Gela Pur C and Gela MP (brandnames)

Technical information

Collagen hydrolysis products for improved technological and sensorial properties :

Gela Pur C and Gela MP (brand names)

Gela Pur C yields excellent results for all baked liver preparations and reduces the loss after baking from 7 % to 3 %, i.e. a 4 % saving, provided that 2 % Gela Pur C is added immediately after the product preparations have been started.

Gela Pur C or Gela MP provides an improvement of the technological and sensorial properties of all heated meat and cutter preparations as to their firmness for cutting, their colour fastness, the enhancing flavour of added herbs. It also offers a higher nutritional value, given the high protein content of the composed milk products.

In salami preparations, Gela Pur C results in a lower aw-value, a shortening of the ripening process by 3 tot 4 days and a clear colour distinction compared to all other salami preparations which do not contain Gela Pur C.

Gela MP is a pre-mix containing pure meat proteins and gives all meat preparations a noticeably enhanced meat and/or liver taste. It increases the natural protein content by 1 % and allows 3 % more liquid to be added, provided that a natural thickening, such as carrageen, is also added.

Both branded products can be used in the entire meat processing industry, in a 50/50 proportion, depending on the product preparation concerned.

If you wish to receive samples, please E-mail ,

with indication of the product for which you wish to receive a sample.

Collagene-hydrolyse products for improved technological and sensorical properties:

Gela Pur C and Gela MP (brandnames).

Without PH Liquid Buffersystem and without Gela Pur C

With PH Liquid Buffersystem and with Gela Pur C

With Gela Pur C: 2%.

Improved economic, technological and sensory

properties for all prepared meat products

Advantages when using PH LIQUID EXTRACT – GELA PUR C

BUFFER PHOSPHATE 60151 – and RED STAR in the meat industry

- Heated canned ham for export

- additives: PH LIQUID EXTRACT 6014 (0.5 % in finished product),

2 % GELA PUR C and BUFFER PHOSPHATE 60151 (0.5 % in finished product)- improvement of the sensory perceptions (colour, taste, aroma and structure) of the product

- stabilization of the colour

- decrease of the NO" level by ± 25 %

- prolonged storage life of the product (restricted growth of microorganisms)

- a higher quality of the product is guaranteed

- perfect cutting properties, without the product falling apart

- additives: PH LIQUID EXTRACT 6014 (0.5 % in finished product),

- Heated ham (shoulder) for the local market

- Standard product

- Product with higher yield

- Product with decreased polyphosphate level

- additives: PH LIQUID EXTRACT 6014 (0.5 %),

2 % GELA PUR C and 0.5 % BUFFER PHOSPHATE 60151- decrease of the NO" level by 50 %

- improvement as to colour, taste, structure, aroma and as to general aspect

- stabilization of the colour

- prolonged storage life

- additives: PH LIQUID EXTRACT 6014 (0.5 %), 0.5 % BUFFER PHOSPHATE 60151,

2 % GELA PUR C and RED STAR 60153 (3-4%)- increase of yield by max. 25 % compared to the standard product

- everything summarized in point A.

- additives: PH LIQUID EXTRACT 6014 (0.5 %), 0.5 % BUFFER PHOSPHATE 60151,

2 % GELA PUR C and RED STAR 60153 (4 %)- increase of

- yield by ± 15 %decrease of polyphosphates by 50 %

- and everything summarized in point A.

- additives: PH LIQUID EXTRACT 6014 (0.5 %),

- Heated ham (shoulder) wrapped in foil

- Standard product

- Product with increased yield

- additives: PH LIQUID EXTRACT 6014 (0.5 %),

2 % GELA PUR C and BUFFER PHOSPHATE 60151 (0.5 %)- foil can easily be removed before cutting

- everything summarized in point A

- additives: PH LIQUID EXTRACT 6014 (0.5 %),

2 % GELA PUR C, BUFFER PHOSPATE 60151 and RED STAR 60157 (4 %)- increase of yield by 35 % maximally

- everything summarized in point A

- additives: PH LIQUID EXTRACT 6014 (0.5 %),

- Heated ham (shoulder) wrapped in foil, coarsely ground by means of a 12 mm plate

- additives: PH LIQUID EXTRACT 6014 (0.5 %),

2 % GELA PUR C, BUFFER PHOSPHATE 60151 (0.5 %), RED STAR 60153 (3 %), flour (4.5 %) and soy isolate (1 %)- increase of yield by ± 75 %

- everything summarized in point A

- additives: PH LIQUID EXTRACT 6014 (0.5 %),

- Pickled meat products (bacon, etc.)

- additives: PH LIQUID EXTRACT 601 or 6014 (0.3 %),

2 % GELA PUR C BUFFER PHOSPHATE 60151 and dextrose (0.2 %)- preserving (low pH) – prolonged storage life

- improvement of colour, taste and aroma

- colour stabilization

- additives: PH LIQUID EXTRACT 601 or 6014 (0.3 %),

- Sausage

- additives: PH LIQUID EXTRACT 601 or 6014 (0.3 – 0.5 %),

2 % GELA PUC C and BUFFER PHOSPHATE 60151 (0.5 %)- improved colour stabilization

- improvement of the aroma

- prolonged storage life

- cutter products

- additives: PH LIQUID EXTRACT 601 or 6014 (0.3 – 0.5 %),

- For all heated liver preparations

- additives: PH LIQUID EXTRACT 6014 (0.3 – 0.4 %),

2 % GELA PUR C and BUFFER PHOSPHATE 60151 (2 to 3 g)- improved colourfastness

- more liver taste

- prolonged storage life : 3 months if vacuum-packed

- liver sausage cook-in system : 9 months, buffer pH : 6

- better cutting and/or spreading properties, depending on the dose of GELA PUR C or GELA MP used

- additives: PH LIQUID EXTRACT 6014 (0.3 – 0.4 %),

- All prepared salami products

- additives: PH LIQUID EXTRACT 601 (0.3 – 0.4 %),

2 % GELA PUR C and 0.2 to 0.3 % BUFFER PHOSPHATE 60152- decreased AW value in case of use of GELA PUR C

- improved colourfastness of the cut surface

- the fatty acids do not turn rancid

- improvement of aroma and taste

- excellent cutting properties; the lard cubes do not fall apart when the product is very finely cut; when cutting automatically and weighing, there are no problems such as the lard cubes coming loose or falling apart

- stable buffering, depending on the choice of the product

- additives: PH LIQUID EXTRACT 601 (0.3 – 0.4 %),

More technical information under construction.

Contact information:

E-mail: info@ph-liquid.com

This website, layout and background is registrated

Send mail to info@ph-liquid.com with questions or comments about this web site.